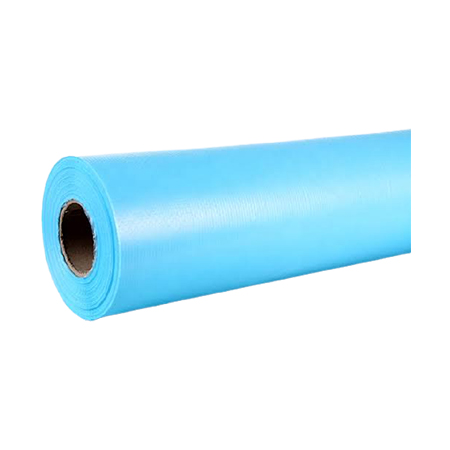

Perforated Release Film

The basic purpose of these release films is to secure the proper release of the material used for assisting the vacuum bagging. This film is known as Vacuum Release Film. Release Films are situated directly in contact with the laminate. They separate the laminate from breather fabrics, which has no release characteristics. These films are available and selected depending on the cure temperature, pressure and complexity of the component and the resin system involved. Release films are often perforated so ensure that any trapped air, volatiles or excess resin, which may compromise the physical properties of the laminate, can be eliminated. Varied types of perforation patterns are available in a range of film options to comply with the various cure temperature requirements, thicknesses, tensile strengths, adhesion, upper service temperatures and many more.