Non Perforated Release Film

Our Products

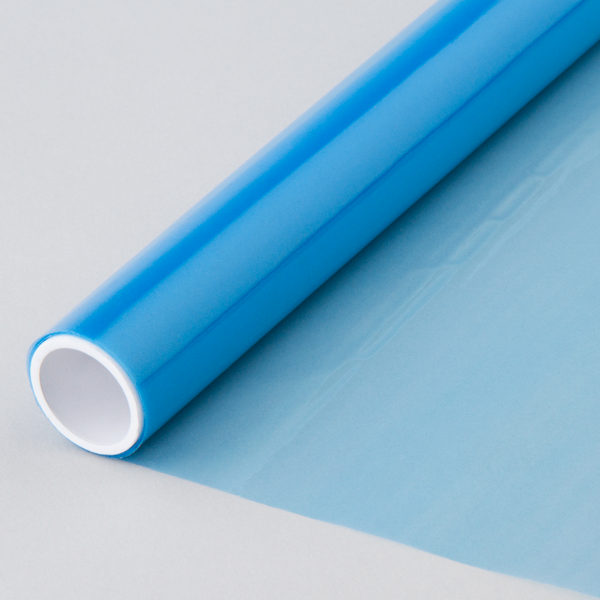

Non Perforated Release Film

The Non-Perforated Release Film is a high-performance material designed for composite manufacturing processes, ensuring optimal resin control and surface finish. This durable film acts as a reliable barrier between the composite material and the breather layer, effectively preventing resin bleed-through and ensuring a clean and smooth surface finish. Ideal for vacuum bagging and other advanced composite molding techniques, this release film is suitable for use in industries such as aerospace, automotive, marine, and sports equipment manufacturing.

Made from premium-grade thermoplastic polymers, the non-perforated release film is engineered to provide excellent heat resistance and chemical stability, making it compatible with a wide range of resin systems, including epoxy, polyester, and vinyl ester. Its high tensile strength ensures durability during the molding process, while its smooth, non-stick surface allows for easy removal from cured composites, minimizing defects and labor-intensive cleaning tasks.

Technical Specifications

| Description | Property |

|---|---|

| Material | High Density Polyethylene |

| Width | 1500mm |

| Thickness | 25 – 35 microns |

| Tensile strength at break (Non Perforated Film) | ≥35mpa |

| Elongation at break (Non Perforated Film) | ≥300% |

| Melting point | ≥125°C |

| Color | Light Blue |

Related products

WE WORK globally

SR Composites FAQ's

What industries can benefit from SR Composites' products?

Our products are widely used in marine, aviation, construction, defense, mass transportation, space, and wind energy industries. Whether you need lightweight materials for aircraft or durable components for wind turbines, we have you covered.

Does SR Composites provide custom solutions?

Yes, SR Composites specialize in developing tailored composite solutions that meet the specific requirements of our clients across industries.

Where are SR Composites’ products manufactured?

Our products are proudly manufactured in Vadodara, Gujarat, using advanced technology and stringent quality control measures to ensure excellence.

What makes SR Composites unique?

SR Composites combines cutting-edge technology, industry expertise, and customer-centric service to offer unmatched vacuum infusion consumables and composite solutions globally.

Can SR Composites deliver bulk orders Internationally?

Absolutely! SR Composites have a robust global supply chain to fulfill bulk orders efficiently and on time.