Knitted Infusion Mesh 125 GSM

Our Products

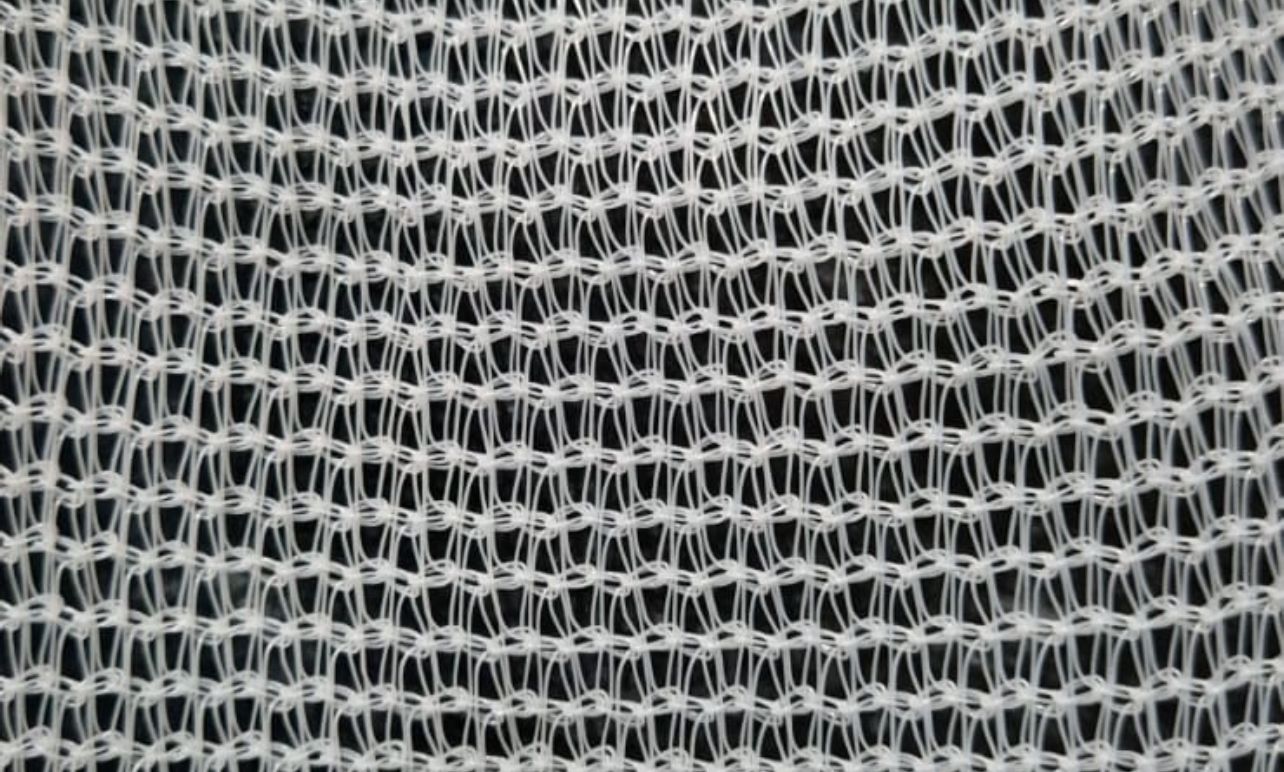

Knitted Infusion Mesh 125 GSM

The Knitted Infusion Mesh 125 GSM is a lightweight yet highly effective material designed to enhance resin flow during resin infusion processes in composite manufacturing. Its open-knitted structure ensures uniform resin distribution across the entire laminate, reducing dry spots and improving the overall quality and strength of the composite product. Ideal for use in industries such as aerospace, automotive, marine, and renewable energy, this infusion mesh is an indispensable tool for achieving precision and efficiency.

Manufactured from durable polyethylene, the knitted design of this mesh offers excellent flexibility and durability, making it suitable for complex mold geometries. With a weight of 125 GSM, it strikes the perfect balance between flow efficiency and ease of handling, ensuring it meets the demands of both small and large-scale composite projects.

Technical Specifications

| Description | Property |

|---|---|

| Material | High Density Polyethylene |

| Weight | 125GSM |

| Thickness of Yarn | 0.23mm ± 0.02mm |

| Number of Wales/Inch | 7 ± 10% |

| Number of Courses/cm | 5 ± 10% |

| Melting Temperature | ≥125°C |

WE WORK globally

SR Composites FAQ's

What industries can benefit from SR Composites' products?

Our products are widely used in marine, aviation, construction, defense, mass transportation, space, and wind energy industries. Whether you need lightweight materials for aircraft or durable components for wind turbines, we have you covered.

Does SR Composites provide custom solutions?

Yes, SR Composites specialize in developing tailored composite solutions that meet the specific requirements of our clients across industries.

Where are SR Composites’ products manufactured?

Our products are proudly manufactured in Vadodara, Gujarat, using advanced technology and stringent quality control measures to ensure excellence.

What makes SR Composites unique?

SR Composites combines cutting-edge technology, industry expertise, and customer-centric service to offer unmatched vacuum infusion consumables and composite solutions globally.

Can SR Composites deliver bulk orders Internationally?

Absolutely! SR Composites have a robust global supply chain to fulfill bulk orders efficiently and on time.